ANAND CY Myutec Automotive implements integrated CAD/CAM software to transform synchronizer ring manufacturing

ANAND CY Myutec Automotive (ACYM), a joint venture between India’s ANAND Group and Japan’s CY Myutec, manufactures high-quality synchronizer rings for passenger cars and commercial vehicles. These components are critical to advanced synchromesh transmissions, which enable smooth gear changes by matching the rotational speeds of gears and shafts.

The company produces a range of synchronizer rings including friction-coated single-cone and multi-cone rings. ACYM often collaborates closely with their customers to develop specialized rings that meet each customer’s specific performance needs.

Meeting design and manufacturing challenges in the automotive transmission market

Emerging technologies, evolving customer demands and a prioritized focus on quality and on-time delivery make the synchronizer ring market a challenging environment, but one filled with opportunities for innovation in materials and design.

To take full advantage of these opportunities, ACYM had to overcome several obstacles in their legacy production environment including:

- Siloed design and production teams using legacy computer-aided design (CAD) software that lacked collaborative features

- Further limitations with the legacy CAD’s software’s inability to support essential aspects of forging design, such as material selection, part geometry, tolerances and undercuts – leading to errors during manufacturing

- Delays and data loss issues caused by compatibility issues with the various file type formats used by ACYM’s customers

- A fragmented workflow that introduced a higher chance of costly errors due to the manual transfer between design and computer-aided manufacturing (CAM) programming phases

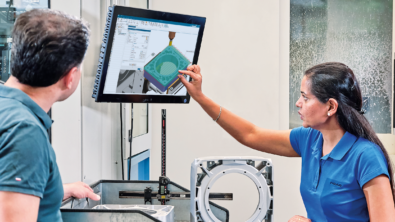

Implementing a strategic approach with integrated CAD/CAM software

To modernize its legacy systems and enhance productivity, ACYM adopted NX CAD and CAM—an integrated, high-performance solution that impressed the company’s design and manufacturing teams. The platform delivered the advanced automation and customization capabilities they needed, streamlining workflows and accelerating innovation. Its powerful toolpath creation features enabled greater precision and efficiency in meeting complex customer demands. The flexible, subscription-based licensing model also made it a cost-effective solution for upgrading.

This new approach produced tangible results for ACYM including:

- Enhanced flexibility in managing design changes

- A 40% reduction in design and production time

- A 30% reduction in associated production costs

- The elimination of multiple software systems resulting in more efficiency and lower costs

- Enhanced cross-team communication and knowledge sharing, breaking down information silos

The advanced surfacing features in NX also facilitate rapid model repairs. Within the NX CAM environment, we can edit part models during programming, enabling us to work faster and streamline collaboration between our design and production teams.

Pranav Rawal , General Manager, ANAND CY Myutec Automotive

Read the full story behind ACYM’s digital transformation journey>>