What’s new in Simcenter Systems Simulation 2504

Simcenter Systems Simulation 2504 has just been released. It contains many exciting new features that will help its users move faster, deal with more complexity, better integrate, and explore new possibilities. This blog highlights this release’s latest features in Simcenter Amesim.

Platform update

The latest release of Simcenter Systems brings a wave of enhancements designed to accelerate workflows, simplify complex simulations, and boost integration across platforms. From smarter radiation modeling using embedded CFD data to faster simulations, resizable sketch icons, and advanced model validation tools, Simcenter Amesim 2504 and Simcenter Flomaster 2504 empower engineers to build, test, and optimize with greater speed and confidence. With support for FMI 3.0 and license-free FMU export, this update makes collaboration and system integration more seamless than ever.

Simcenter Systems 2504

Enhancing modeling efficiency – Resizable icons in Simcenter Amesim sketch

Simcenter Amesim streamlines modeling with resizable icons in its sketch environment. This intuitive click-and-drag functionality allows engineers to emphasize key components and subsystems, providing them with the prominence they deserve.

Supporting all Simcenter Amesim components, including supercomponents and statecharts, resizing maintains design integrity with preserved aspect ratios. This feature enhances the sketch environment, allowing dynamic presentations and quick adjustments such as copy/paste scaling and reset scaling.

With Simcenter Amesim’s resizable icons, engineers can efficiently focus on critical elements, ensuring clarity while modeling complex systems.

Speeding up complex models – Simulation acceleration in Simcenter Amesim

As systems grow in complexity, simulation models can become cumbersome and time-consuming. Simcenter Amesim has introduced a new adaptive tolerance algorithm to enhance it solver efficiency.

This improvement reduces processing times, allowing engineers to gain quicker insights and make rapid decisions. On average, simulations run 19% faster compared to previous versions, helping tackle challenges posed by electrification in both current and future systems.

With faster processing, Simcenter Amesim enables engineers to navigate complexity swiftly, boosting productivity and innovation.

Ensuring model validation – Test execution manager in Simcenter Amesim

Simcenter Amesim introduces the test execution manager to streamline the validation of models and library developments, along with Simcenter Amesim upgrades. This non-regression testing tool efficiently compares simulation results against test cases, ensuring reliability across updates.

Engineers benefit from facilitated testing of new developments, seamless upgrading of software versions, and the ability to execute tests both locally and remotely via a web page. The test execution manager keeps your models validated and integrated, supporting continuous development and innovation with confidence.

Enhancing model integration – FMI 3.0 co-simulation import in Simcenter Amesim

Simcenter Amesim enhances model integration through the support of FMI 3.0 co-simulation import. This feature facilitates the assembly of heterogeneous models using the latest FMI version, offering flexibility with fixed-size and tunable elements and parameters.

With this capability, engineers can import a variety of virtual ECUs, including those with arrays, and 3.0 FMUs from tools like Simulink, Dymola, and others. It also enables the mixing of multiple 3.0 and 2.0 FMUs, enhancing compatibility and integration across platforms. Moreover, engineers can apply distinct run settings for each imported FMU, ensuring precise simulation control and effective collaboration.

Simplifying model sharing – License-free FMU export in Simcenter Flomaster

Simcenter Flomaster introduces a new license option for exporting FMUs that operates without the need for a license server connection, addressing the challenge of using embedded solver FMUs offline.

This feature facilitates the easy deployment of FMUs to offline platforms, streamlining workflows when license servers are inaccessible. Additionally, it enables the sharing of models with external partners, enhancing collaboration and integration efforts across different teams and organizations.

Electrification

As electrification reshapes industries, engineers face growing challenges in battery development, from performance testing to thermal management and aging analysis. The Simcenter Systems 2504 release takes battery simulation to the next level, introducing powerful new tools that make modeling more intuitive, accurate, and aligned with real-world testing. From an enhanced battery cycler to smarter aging models and guided pack design, discover how Simcenter helps you build better batteries faster.

Battery

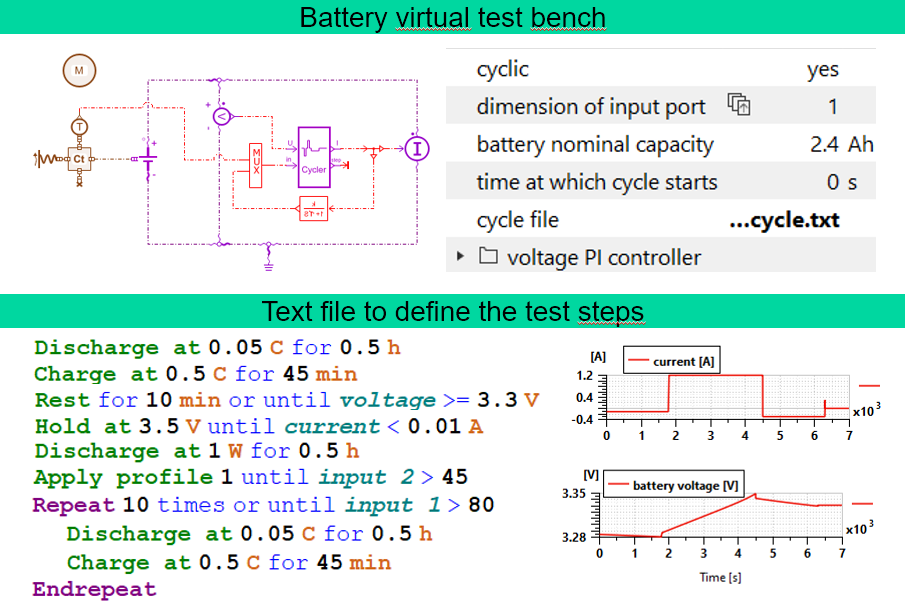

Empowering advanced battery testing – Enhanced battery cycler

Evaluating battery performance across multiple charge and discharge cycles can be both technically demanding and time-consuming. With the release of Simcenter Systems 2504, we’re introducing an enhanced battery cycler that makes this process significantly easier—and more realistic.

Instead of configuring every step manually, engineers can now define entire test sequences through a simple, human-readable text file. Each test can include a range of actions, from basic charging and discharging cycles to custom current profiles, looped sequences, and specific event-based conditions. It’s as close as you can get to operating a real battery test bench—without the hardware.

This improvement allows for a much more flexible and intuitive way to run performance assessments and optimization routines, enabling users to simulate complex scenarios and make smarter design decisions, faster.

Innovating battery longevity analysis – Electrochemical aging model enhancement

Understanding battery aging is vital for engineers as various degradation mechanisms can affect performance and lifespan. Simcenter addresses this challenge with its enhanced battery P2D electrochemical model, which employs advanced pseudo-2D and single-particle modeling capabilities.

This innovative model helps identify key degradation mechanisms like positive electrode dissolution, SEI layer growth, and lithium plating. Furthermore, it facilitates the automatic evaluation of effective battery capacity, enhancing both design and operational performance.

With this tool, engineers gain valuable insights into battery aging, empowering them to optimize energy storage solutions for increased reliability and efficiency.

Energy and thermal management

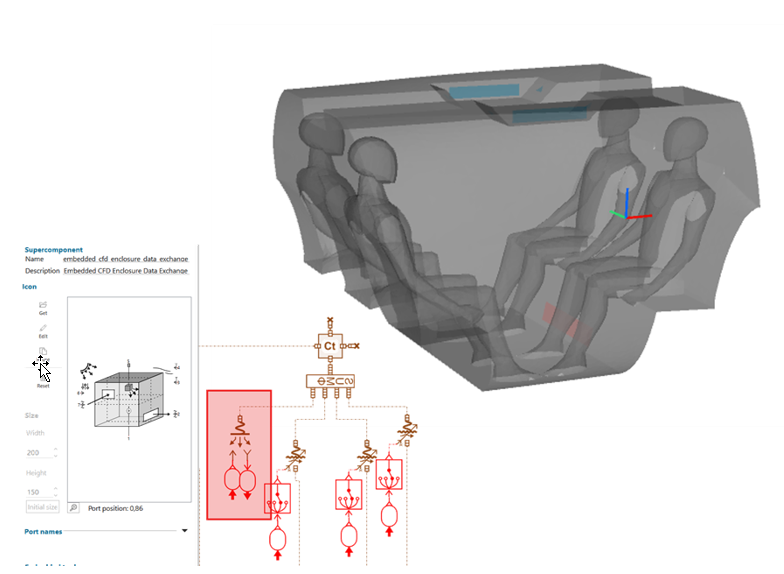

Simplifying complex cavity radiation modeling – Embedded CFD data exchange

Simcenter’s Embedded CFD feature revolutionizes thermal comfort management by modeling complex cavity radiation using predictive 3D capabilities in a 1D model. This approach extracts view factors from 3D and translates them into the 1D radiation model.

Engineers benefit from automated 3D factor computation and retrieval from Simcenter STAR-CCM+ directly within 1D models. By using user-defined 1D enclosure boundaries, the solution provides automated and efficient resolution of finite radiative fluxes, enhancing system design accuracy and thermal performance.

Streamlining battery pack modeling – Battery pack assistant

Evaluating battery performance alongside its cooling capabilities presents significant challenges, particularly due to the complex interplay of the physics involved. To streamline this process, Simcenter introduces the battery pack assistant, designed to guide engineers in generating comprehensive multi-physics models.

This user-friendly tool offers an intuitive workflow that empowers users to define complex battery systems with visual control over every step. By enabling the simultaneous generation of both battery and cooling models—whether direct or indirect—the battery pack assistant enhances modeling efficiency.

Further customization is facilitated through a customizable discretization approach, focusing on specific zones to yield accurate results. The assistant also allows for the generation of an open and easily customizable Simcenter Amesim model.

With the battery pack assistant, engineers can confidently navigate the complexities of battery and cooling performance, ensuring optimized designs and improved thermal efficiency.

Micro-channel heat exchanger integration – Heat Exchanger Assistant

Modeling micro-channel heat exchangers often presents a significant challenge due to the detailed setups required and the need for flexibility to accommodate various configurations. To facilitate this complex process, Simcenter introduces the heat exchanger assistant (HEXA), designed to guide users through the creation of highly detailed and customizable models.

The HEXA tool provides a user-friendly workflow that simplifies the design of micro-channel heat exchangers, leading users step-by-step to reduce complexity and errors. Its intuitive sketch generation feature allows for rapid model creation without compromising customization options, enabling even non-experts to build comprehensive models that meet specific project requirements.

Additionally, the assistant allows for adaptations to match unique and exotic configurations, ensuring that every design fits perfectly with project specifications. By leveraging HEXA, engineers can efficiently harness the underlying model predictability, enabling easy access to key parameters and enhancing overall design accuracy in heat exchanger modeling.

Hydrogen

As hydrogen emerges as a key pillar in the shift toward sustainable energy, engineers need robust tools to model, test, and optimize every part of the production and storage process. With Simcenter Systems 2504, the hydrogen capabilities are expanded through a predictive alkaline water electrolyzer component and a dedicated fluid storage library for cryogenic systems. These innovations simplify system design, boost efficiency, and enable data-driven decisions, empowering engineers to lead the way in hydrogen innovation.

Enhancing hydrogen production efficiency – Simcenter’s alkaline electrolyzer component

Engineers working on hydrogen production face the challenge of assessing the performance of alkaline electrolyzers under varying operating conditions with limited data. Simcenter addresses this with its comprehensive alkaline electrolyzer component, providing a solution that significantly enhances efficiency in green hydrogen production.

This component allows engineers to swiftly explore the potential of alkaline electrolyzers across different conditions using a limited experimental dataset for parameter setting. The integration of this predictive AWE component within Simcenter’s suite streamlines the hydrogen production process, enabling quick balance of plant sizing and control design. With these capabilities, engineers can optimize hydrogen systems more effectively, supporting the transition towards sustainable energy solutions.

Revolutionizing cryogenic storage design – Simcenter’s fluid storage library and LH₂ dormancy demo

In industries like aerospace and automotive, efficient cryogenic fluid storage is essential. To assist engineers, Simcenter introduces its innovative fluid storage library, paired with the liquid hydrogen dormancy demo. This library offers novel components tailored for modeling self-pressurization and boil-off in cryogenic tanks.

The LH₂ dormancy demo provides engineers a quick way to harness these components, facilitating system modeling that aligns closely with experimental data. Engineers can now accurately estimate pressure buildup and temperature variations due to heat input.

This capability proves invaluable, allowing precise design and optimization of cryogenic storage systems. By integrating these new tools, Simcenter aids engineers in overcoming complex challenges, pushing forward advancements in cryogenic storage across various critical industries.

Chassis engineering

Streamline your workflow with real-time capable MBS suspension models

For engineers working on vehicle dynamics, transitioning complex suspension models from established 3D software to real-time simulations can be a daunting task. Simcenter Amesim addresses this challenge with its new offering: seal-time capable MBS suspension template models, supported by a dedicated graphical user interface (GUI).

This innovative solution simplifies the migration process by providing pre-defined suspension system templates that seamlessly integrate 3D CAD data into Simcenter Amesim. Engineers can now preserve the integrity of their initial designs while adapting them for real-time simulation needs, ensuring precision and efficiency in vehicle dynamics.

The ready-to-use templates eliminate the time-consuming task of building models from scratch, allowing engineers to focus on optimizing design and functionality. With the real-time capable MBS suspension template models, Simcenter Amesim empowers engineers to enhance their modeling experience, enabling smoother, more reliable transitions to dynamic simulations in vehicle dynamics.

Enabling accurate EV and H₂ truck modeling – Vehicle database enhancement

In response to the evolving transportation landscape, Simcenter presents its enhanced vehicle model databases to address engineers’ need for precise modeling of new electric vehicles and hydrogen trucks. By utilizing correlated starters and integrating comprehensive test data, engineers gain access to ready-to-use models of vehicles like the Hyundai Ioniq 6, BYD Atto 3, and various hydrogen-powered trucks.

This advancement allows for exceptional simulation fidelity, empowering engineers to confidently evaluate and optimize next-generation vehicle solutions. With Simcenter’s enhanced database, the complexities of new vehicle technologies are navigated more effectively, pushing the boundaries of innovation in sustainable transportation. These validated models provide engineers the accuracy required to develop more efficient, reliable transportation solutions, leading to a greener future.

Harmonizing chassis design solutions – New framework for tire modeling

In the quest to evaluate electric chassis designs across an array of range, comfort, and drivability scenarios, engineers have encountered the challenge of managing diverse tire models within vehicle dynamics solutions. Simcenter addresses this need with its new framework for tire modeling. This innovative approach offers a simplified and harmonized structure, enabling seamless integration and consistency across all tire models.

The true value of this framework lies in its contribution to comprehensive chassis design evaluation. With compatibility across various road description formats and dynamic modulation of grip, engineers can effortlessly interface tire modeling software with the complete design process. This ensures that every aspect of tire performance is accurately represented, providing engineers with the tools needed to optimize electric vehicle design and innovate beyond limits.

Learn more about the Simcenter Systems simulation 2504 release in the What’s New video